Doosan Bobcat Brings the Future of Work, Today

AI-driven features simplify the jobsite while making it more efficient.

A daily selection of features, industry news, and analysis for AV/IT professionals. Sign up below.

You are now subscribed

Your newsletter sign-up was successful

For nearly 70 years, Doosan Bobcat has redefined how work gets done on the jobsite. The company came to its eighth CES introducing a wave of new AI and next-generation intelligence designed to simplify work and give jobsite confidence to operators, dealers, and customers alike.

[CES 2026: LEGO Introduces a New Dimension of Play in a Galaxy Far, Far Away]

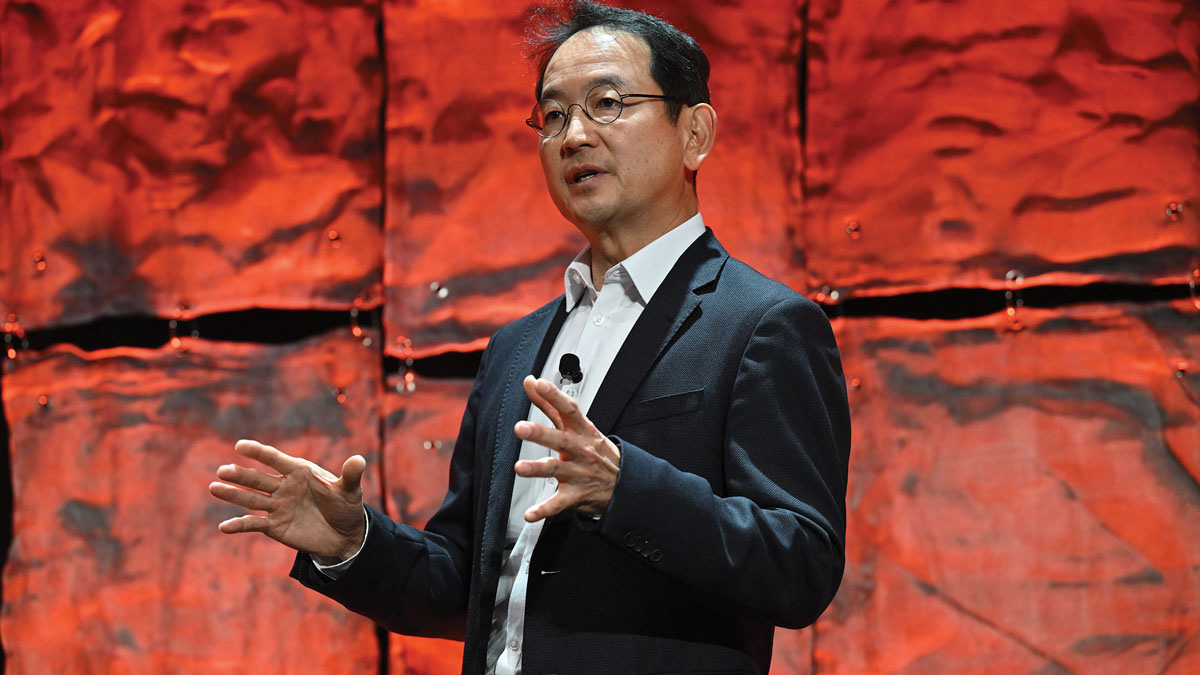

Per a report from the Association of Equipment Manufacturers, more than 40% of the United States’ construction workforce will retire by 2031. That means machines need to be designed for those new to them, as well as for the 20-year veterans on the jobsite. That’s why, explained Scott Park, CEO and vice chairman, Doosan Bobcat, the company has transformed from a hardware-only carrier to an intelligent, software-enabled ecosystem.

Buzzwords like AI, electrification, autonomy, and connectivity are set to dominate the CES floor, and visitors to Bobcat’s booth will see all four in action. Under the slogan “Watch Us,” Bobcat attempts to do today what many expect can only be done in the distant future.

Joel Honeyman, VP of global innovation, Doosan Bobcat, took the stage to unveil four new, AI-enabled powered solutions. He reminded us that these intelligent solutions are not here to replace the worker, but to empower those who get the work done, whether it is a brand-new employee or a veteran in the construction industry. The four innovations set to simplify the operator’s experience are:

Bobcat Jobsite Companion: AI-driven, this intelligent solution can be personalized to each operator and partner on the jobsite to provide clarity and seamless integration. The technology provides real-time support and automation for machines powered by Bobcat’s proprietary AI LLM.

Service.AI: Downtime is a large pain point that equates to lost time and lost revenue. Service.AI minimizes downtime by providing access to Bobcat’s repair expertise, full repair manuals, warranty details, and real-time diagnostic guidance and troubleshooting.

A daily selection of features, industry news, and analysis for AV/IT professionals. Sign up below.

Collision Warning and Avoidance System: Bobcat’s new system provides jobsites with a sophisticated imaging radar system and AI technology that rapidly analyze areas around the machine, providing automatic alerts and slowing down or even stopping the machine.

Advanced Display Technology: This system allows Bobcat to provide real-time awareness without distraction. The cab window is transformed into a digital space that displays barriers and obstacles with collision warnings and boundaries, providing clarity for new operators and confidence for experienced ones.

Before Park and Honeyman left the stage, they surprised the crowd with one last announcement. The two shared the concept of the RogueX3, combining autonomy, electrification, connectivity, and modularity into one machine. Or, as Park said, it isn’t simply a machine, but a platform to enable the future of work, turning challenges into solutions. It is designed to fit the work that needs to be done, and while currently electric, can also be hybrid, diesel, or even hydrogen powered.

“Were not changing who gets the job done,” Park concluded. “We’re transforming how the job gets done.”

Wayne Cavadi is the senior content manager of Systems Contractor News. Prior to taking a leap into the Pro AV industry, Wayne was a journalist and content lead for Turner Sports, covering the NCAA, PGA, and Major and Minor League Baseball. His work has been featured in a variety of national publications including Bleacher Report, Lindy's Magazine, MLB.com and The Advocate. When not writing, he hosts the DII Nation Podcast, committed to furthering the stories and careers of NCAA Division II student-athletes. Follow his work on Twitter at @WayneCavadi_2 or the SCN mag Twitter page.