Chip-On-Board Technology: The Future of Fine Pixel Pitch LED Video Displays

COB Technology Provides the Stability Needed For Pixel Pitches Below 1 That SMD Cannot Achieve

A daily selection of features, industry news, and analysis for AV/IT professionals. Sign up below.

You are now subscribed

Your newsletter sign-up was successful

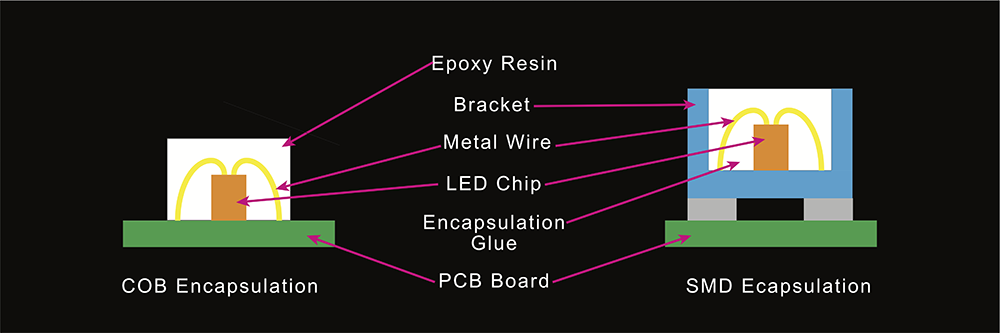

Chip-On-Board (COB) Technology solders three very fine LED chips—one red, one blue, and one green, directly to the PCB Board resulting in a flat, uniform LED surface. This flat, uniform LED surface enables a flawless encapsulation of the LED chips using an epoxy resin finish. The SMD process encapsulates three chips into a bulb/lamp, that are then affixed to the PCB board. It is not possible to achieve a perfectly flat surface using SMD bulbs.

COB Technology is a two-step manufacturing process as opposed to the four-step SMD process. The COB manufacturing process eliminates the need for brackets and supports, thereby reducing the number of soldering points. Fewer soldering points result in fewer possible failure sites. COB Technology is up to 10 times more reliable than SMD. 10/pp versus 50-100/ppm. The lamp failure rate is extremely low (see diagram below).

COB Technology allows for the development of small, reliable pixel pitches. SMD bulbs take up a plethora of space, relatively speaking. COB does away with bulbs and, thereby, creates more space to allow for more pixels to be inserted into an equal area. SMD 0808 and mini 4-in-1 are simply not stable below a pixel pitch of 1.

The encapsulation of the fine LED chips in the COB manufacturing process uses clear epoxy resin to create a protective surface that is highly impact-resistant.

This protective surface is also a barrier to moisture and is waterproof on the front.

COB Technology is anti-static and anti-dust.

COB Technology also provides for a higher contrast ratio, sharpness, and deeper colors than SMD.

A daily selection of features, industry news, and analysis for AV/IT professionals. Sign up below.

Chromium is Vanguard LED Displays’ COB Series. Features include:

- Fully front-serviceable.

- No external jumpers on the rear, making this cabinet ideal for wall mounting

- Gold wired LEDs

- Universally used Novastar or Colorlight operating systems

- No internal cables

- At only 2.28-inches deep, Chromium cabinets are designed for wall mounting or can be recessed into a wall and meet ADA requirements

- Pre-threaded mounting locations make installation simple

- Magnetic LED modules make module replacement quick and easy

- Vanguard LED Displays offer a five year warranty and five percent spare parts

- IC drivers allow for customizable refresh and scan rates

- Receiving cards allow for custom gray scale levels from 14 to 18 bit

- Redundant power and data configurations are available

- No internal ribbon cables. There is a single, cableless PCB connection for data and power

- Seam brightness compensation is standard

- 3840hz refresh rate

- Smart module data retention. The display modules are hot swappable and do not need recalibration or reconfiguration after being serviced or swapped

- Color brightness uniformity

- DC-DC remote power supply

- Low latency available—reduction from 4 frames to .5 frames

This post was sponsored by Vanguard. Any content in this blog should not be considered an endorsement by AVNetwork.com. Any claims made in this blog are the responsibility of the author.

Read the previous entries in this blog series here:

Blog #1: Caveat Emptor - Buyer Beware

Blog #2: Flex Cabinets: The New Way to Create Curved LED Displays

Blog #3: LED Fine Pixel Pitch Video Displays Using Surface Mounted Devices (SMD) Bulbs Have Hit the Wall