Laser Precision

A daily selection of features, industry news, and analysis for AV/IT professionals. Sign up below.

You are now subscribed

Your newsletter sign-up was successful

Shedding Light On Fiber Optic Test Methodology And Equipment It’s all too easy to overlook a very important aspect of fiber optic equipment and systems—testing. I can’t begin to count how many times either myself or my colleagues have been on the other end of

Optical light source phone conversations trying to assist someone with setting up and troubleshooting their fiber optic system, only to find that the integrators had neither optical test equipment nor the proper knowledge to use what they did have. In order to make the installation and integration of fiber optic systems as enjoyable and painless as possible, it’s important to have at least the minimum of fiber optic test equipment to help facilitate a smooth and pleasurable experience!

There is a plethora of test equipment available for fiber optic equipment and system testing. The most common and useful are the following: Optical power meter (OPM), Optical light source, Optical loss test set, Fiber fault locator, Optical connector inspection scopes and the Optical Time Domain Reflectometer (OTDR).

Optical Power Meter (OPM): The most basic and useful (and essential) of the test equipment is the optical power meter. This is equivalent to an electrician having a volt meter. The OPM allows you to measure optical transmitter output power, power at various junction (connector or patch panel) points, and receiver input power. In many cases, the optical power meter will be all that you need to properly diagnose a system problem and get the system up and running quickly.

Optical power meter transmitter’s own light source, the OPM can be used to measure the transmitter’s output power, the light exiting the fiber at the receiver, as well as the light from the fiber at various interim points such as patch panels, etc. In this way, you can compare the readings on the meter to the specifications of the fiber transmitter, fiber loss, and overall optical loss budget. The OPM can also be used to measure the difference between two readings, thus providing an optical loss figure that may represent the overall loss of the fiber span. The transmit (Tx) power minus the received (Rx) power (dBm - dBm = dB) gives you the value of the fiber system link loss. A good, basic power meter can be purchased for about $400 to $500. That’s a very wise investment!

Another power meter is available for measuring the optical powers of up to 16 individual CWDM (Coarse Wavelength Division Multiplex) lasers. This power meter will provide both a digital display of the wavelength’s absolute power and a bar graph of all the selected wavelengths on one display. This allows the user to monitor the optical characteristics of each optical transmitter in the CWDM system simultaneously, saving time and money when troubleshooting the system.

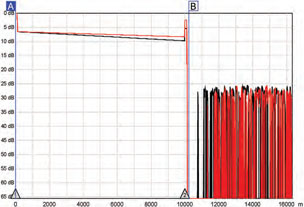

OTDR trace 1310nm and 1550nm. More flexible OLS units will have light sources applicable to both multimode and singlemode fiber. When used in conjunction with an OPM, the entire fiber infrastructure including fiber, splices, and connectors can be tested at different wavelengths to verify the fiber installation’s integrity, without the need for any transmitter/receiver equipment. Since an OPM and OLS are used at different ends of the fiber, two persons are required to properly test the fiber. OLS prices range from $1,000 to $5,000 depending on type of source(s), LEDs and/or lasers, and wavelengths.

A daily selection of the top stories for AV integrators, resellers and consultants. Sign up below.

Optical Loss Test Set (OLTS): There are different versions of the OLTS some of which are basically a package containing a separate OPM and OLS while others combine both the functions of the OPM and OLS in a single, portable unit. While the basic units still require two persons to properly test a system (one at each end), there are automated OLTS units that communicate with each other and allow one user to change the operating parameters of both units from one end to test the fiber at different wavelengths. Prices for the OLTS range from $1K to $10K, depending on how feature-rich the units are.

Optical loss test set adapter for launching the light into the fiber under test. They are basically a red laser pointer designed specifically for coupling the light into a fiber connector. They can be used with either multimode or singlemode fiber and can identify fiber breaks, bad connectors and splices, sharp bends (microbends), and can also be used as a fiber identifier. In the presence of a broken fiber, the visible laser will shine through the break and leak out through the cladding and through the jacket of a standard fiber jumper or pigtail giving a visual indication of where the break or bend is located. Distances in excess of 2km can be checked for continuity. A fault locator can be obtained for a few hundred dollars. Fiber fault locators are quite affordable and range in price from $200 to $500.Optical Connector Inspection Scopes: One of the problems working with fiber in the AV and broadcast world is that cables are continuously being run in environments that are less than pristine in terms of cleanliness. Unprotected, the connector end faces can become very dirty causing high losses and potentially compromising the loss budget and performance of the optical link. The optical inspection scope is used to visually check the end surface of the connector and identify contamination or damage to the connector end face. The most common and portable one is basically a microscope with an optical connector port and internal light source to illuminate the connector front surface. They typically have 200X magnification so that you can easily see the optical core of both singlemode and multimode fibers. The typical

Optical inspection scope price range for these inspection scopes is $500 to $2,000. The more expensive digital scopes can store images of the connector ports for future comparison.

Optical Time Domain Reflectometer (OTDR): The OTDR is a versatile, one-person instrument that identifies and quantifies events such as fiber distance and attenuation, connector and splice losses, and fiber breaks. In addition, it will measure the distance to these events as well as the total length of the fiber. Some of these events are characterized as expected (such as connector loss) while some are unexpected, such as fiber breaks, sharp fiber ‘kinks’ or tight bends, etc.

The OTDR works by sending very short, high-intensity pulses of light down the fiber and measures the reflection or backscatter of this light as it propagates down the fiber. By measuring the time it takes for the pulse of light to return as well as its amplitude, the OTDR will calculate the distance to these events as well as the magnitude of each. It is a very versatile and effective way to perform single-ended testing and troubleshooting of a fiber link. However, this versatility comes at a price. The cost of a basic, portable OTDR is in the range of $5,000 to $8,000. While not for everyone, the OTDR can save time and money in diagnosing a fiber problem to ensure that system downtime is held to a minimum. While the OTDR is straightforward to use, it does require a higher set of skills and some initial training to help better understand its functions, capabilities, and limitations.

All of these pieces of test equipment have different adapters to allow them to mate with various optical connectors including ST, FC, LC, and SC types.

You can receive additional information on these tools and other fiber optic test equipment by contacting The Light Brigade (www.light brigade.com), a fiber optic training company.